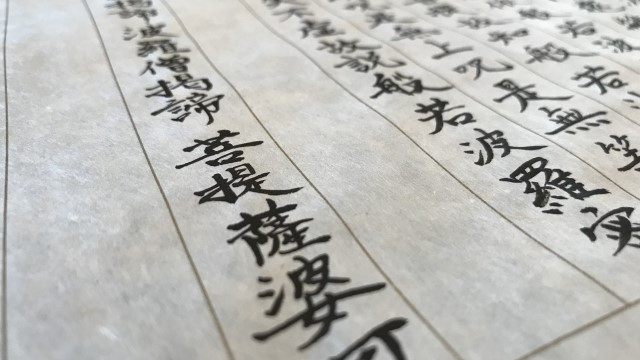

About Washi (Japanese paper-和紙)

Washi is one of the most representative of Japanese lifestyle and culture and is a traditional paper of Japan. It refers to paper made in Japan instead of Western paper, which was introduced from Europe and the United States.

Washi is used not only in Japan but also in the restoration of cultural properties around the world due to its preservation, flexibility, and stability. They are also solid and durable, so Japanese umbrellas and even kimonos are made of paper.

It is said that Japanese fans, called Sensu, and Japanese lanterns, called Chochin, were born in Japan because Japanese paper, which is resistant to folding, was used.

The life span of Japanese paper is said to be 1000 years, while the life span of Western paper is said to be 100 years.

The beginning of Washi, Japanese paper

The technique of making paper from linen fibers was invented in China.

There are various theories about the origin of Japanese paper, but the prevailing theory is that it was brought to Japan by Buddhist monks from Korea in 610. A family registered using Japanese paper in 702 in the Shosoin Repository in Nara prefecture is said to be the oldest domestic paper in Japan.

In the Nara period (710-794), Kozo, which is easier to process than linen fibers, was used as a raw material.

As Buddhism flourished, so did the demand for paper for transcribing sutras. In the Heian period (794-1185), Japan’s unique papermaking technique was established, and thin, strong, and beautifully lustrous Japanese paper was born.

During the Edo period, various processed products were produced in multiple parts of the country to add color to the lives of ordinary people.

Raw material for Japanese paper

Plants such as Kozo, Mitsumata, and Gampi are the primary raw materials of Japanese paper.

Kozo (楮)

The majority of Japanese paper is made from Kozo. Because of its long fiber and toughness, Kozo is used in a wide range of products. Kozo grows wild in the mountains and is easy to produce.

Mitsumata (三椏)

Mitsumata is characterized by its short fibers. Suitable for printing and used for postcards and letter paper, Mitsumata is a tree that originated in China and has been used since the Edo period.

Ganpi (雁皮)

Ganpi, like Mitsumata, has short fibers and a smooth paper surface with a beautiful finish.

Ganpi is challenging to produce, and production is low.

The beautiful luster of Ganpi paper has long been used for luxury products.

Water is essential for making Japanese paper

Water is the most critical factor in making Japanese paper.

Good quality water is required in washing and papermaking, called Nagashisuki, the raw material Kozo in water.

Soft water, low in calcium and magnesium, is suitable for making Japanese paper.

When we try to make Japanese paper with the tap water that we usually use, it is said that it turns red and discolored after a few years because it contains chlorine.

Water is just water, but water is essential. The quality of the paper is affected by the slight difference in the ingredients in the water.

A papermaking technique called “Nagashisuki” for making Japanese paper.

The basic technology for making paper came from China.

Later, however, Japan invented its method of handmade paper, which is called “Nagashisuki.”

It is a method to mix mucilage called “Neri” with raw materials paper, shake the paper material liquid, and make it easy to entangle the fibers with each other. The process is repeated several times, removing excess water and pumping in the paper material again.

It was popularized around the end of the Nara period (710-794), and it spread to many places because of its thin but strong paper.

The difference between Japanese paper and Western paper

| Japanese paper | Western paper | |

| Features | Depending on the region and ingredients, each has a different feel and look. | Constant quality and mass production is possible. |

| Materials | Kozo, Mitsumata, Ganpi | Broad-leaved trees, coniferous trees, etc. |

| Surface | Rough and uneven | Smooth and uniform |

| Fiber length | Relatively long | Relatively short |

| Printing | Hard to print | Easy to print |

In addition to the above, Japanese paper is highly preservative.

Discoloration and deterioration are also likely to occur in Western paper compared to Japanese paper.

However, since Japanese paper is handmade, it is unsuitable for mass production. It is said that the production speed of cutting paper is limited to about 200 sheets a day, even for skilled craftsmen.

Where Washi is produced

Washi is produced all over the country, from Hokkaido to Okinawa, and some of them have a long history, while others have just started in recent years.

Sekishu Washi in Shimane, Honmino Washi in Gifu, and Hosokawa Washi in Saitama were registered as Intangible Cultural Heritage of UNESCO in 2014.

There are three points in common between these washi.

・The raw materials are domestically produced by Kozo.

・There is a river with good quality water nearby.

・Traditional papermaking technique has been handed down from generation to generation.

In addition, Echizen paper, Mino paper, and Tosa paper, which are said to be Japan’s three Yamato papers, are also famous.

Products made from Japanese paper

Washi is stationery for writing letters and pictures and has also been used to wrap things.

It has such a wide variety of uses that it is used for Fusuma, Shoji (paper sliding doors), Japanese lanterns, called Chochin, Japanese fans, called Sensu, clothes, and vessels.

Chiyogami

Wagasa-Japanese umbrella